plastic injection moulding

Injection molding of thermoplastic material articles

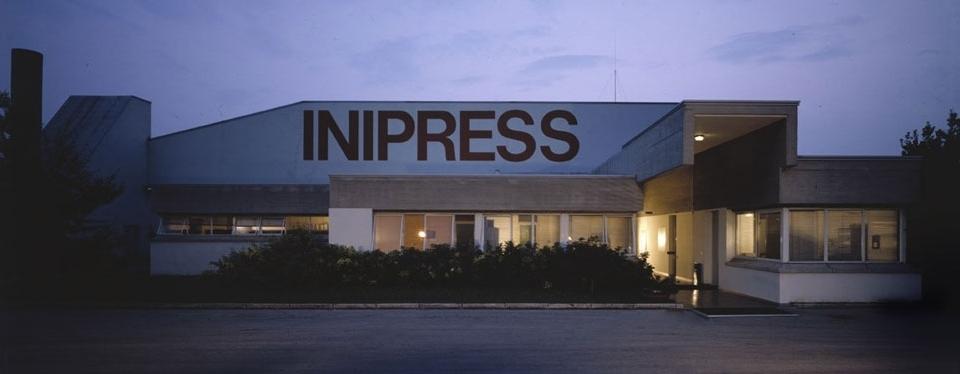

INIPRESS SpA specializes in plastic injection molding of items and components for different business areas: furniture and design, automotive, technical items and sports items, cosmetics packaging, food and canning industries, toys, homewares and more. At our company plant in the province of Treviso, we work different types of thermoplastic materials: commodities (PP, PE, PS, ABS) technopolymers (PA, PC, PPO, POM), aesthetics (SAN, SMMA, ABS, PMMA), special ( TPU, POM, ABS / PA, MABS, PBT / PC, TPC, Alcryn), renewable and recycled (RPP, RPE, WPC, Mater Bi) and elastomers (SBS and SEBS).

How is the process of injection moulding carried out

INIPRESS customers can rely on a very high level of competence, dynamism and upgrading. Our technicians are constantly experimenting - with innovative equipment - on new technologies, researching and developing unpublished processing methods of materials, producing prototypes and providing qualified assistance to designers and manufacturers.

At INIPRESS we are equipped with an advanced production system that enables the monitoring and programming of the production in real time.

The injection moulding process takes place by melting the material that is originally in granule form and injecting it into a mould to obtain the form. Once it is cooled the article is removed by ejectors and picked up by a robot.

Custom-design of plastic articles

At INIPRESS, we support our clients in each of the industrialization phases of the product: from the creative idea to the 3D realization, from prototyping to the processing and mechanical simulations to the realization of the mould using CAM, from the choice of the most suitable thermoplastic material up to the injection moulding of the article. At our plant in Treviso we are also involved in the post-production machining, assembly and final packaging.